Troubleshooting industrial control panels is a crucial skill for maintaining the efficiency and reliability of your manufacturing operations. These complex systems, consisting of numerous components like PLCs, relays, and circuit breakers, are the backbones of industrial automation processes. However, when issues arise, they can disrupt your operational flow and lead to significant downtime.

Let's look at the basics of troubleshooting your industrial control panel and some tips and techniques to help you quickly identify and resolve problems.

Understanding the Control Panel

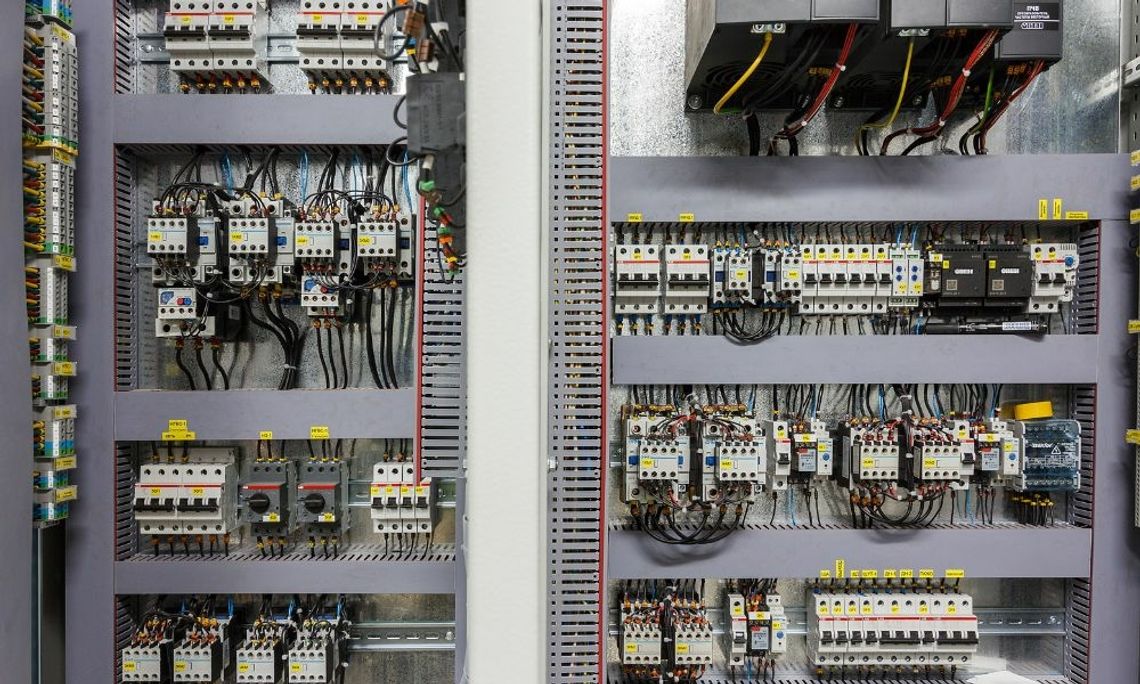

Before diving into troubleshooting, it's essential to have a basic understanding of your control panel. An industrial control panel is a collection of electrical components that work together to monitor and control various automated processes. It typically includes power supplies, input/output modules, relays, PLCs (programmable logic controllers), and other devices. These components can create a network communicating and controlling the different processes.

Identifying Common Problems

Several issues can arise in an industrial control panel, but some of the most common problems include electrical malfunctions, faulty components, and communication errors. Here are some signs that may indicate a problem with your control panel:

- Power issues, such as frequent tripping of circuit breakers or blown fuses

- Unexpected shutdowns or system failures

- Erratic behavior from automated processes

- Malfunctioning sensors or input/output devices

- Communication errors between components

If you notice any of these signs, addressing them promptly is essential to avoid production delays and potential safety hazards.

Troubleshooting Steps

When beginning the troubleshooting process, it's vital to approach the issue methodically and avoid jumping to conclusions. Start by verifying that all basic electrical connections are secure and properly functional.

This verification includes ensuring the power supply is stable and all switches and circuit breakers are in the correct positions. Once you've confirmed the basics, observe the control panel's behavior for any irregularities or warning signals that may point out specific areas of concern. Next, examine the input/output modules and communication lines for faults. These could be loose connections, damaged wires, or any signs of wear and tear that could impair functionality.

Consulting the control panel's documentation can provide valuable insights into potential issues and guide you toward the malfunctioning component. Should these steps not yield a solution, consider seeking assistance from technical support or an experienced technician specializing in industrial control systems. Their expertise can be invaluable in diagnosing and rectifying complex issues.

Preventative Maintenance

One of the best ways to avoid control panel issues is by implementing regular preventative maintenance. This maintenance involves performing routine checks and inspections on all components, ensuring they’re clean, functioning correctly, and free from potential danger or damage. Regularly testing the control panel's performance can also help identify any underlying issues before they escalate into major problems.

Additionally, keeping all documentation and records up to date can aid in troubleshooting by providing a reference point for previous issues and solutions.

Troubleshooting your industrial control panel requires a thorough understanding of its components and the ability to approach problems logically. By following these steps and implementing practices for maintaining industrial control panels, you can ensure your manufacturing processes are smooth and efficient. Remember to always prioritize safety when handling electrical systems, and don’t hesitate to seek professional assistance if needed.

Comment

Comments