Efficient cooling is critical in plastic manufacturing. It not only ensures product quality but also improves production timelines and cost-efficiencies. If you’re looking to make cooling more efficient for plastic parts, you’re in the right place. We’ll introduce you to a few simple yet effective ways to optimize cooling systems for plastic parts.

Optimize Mold Design

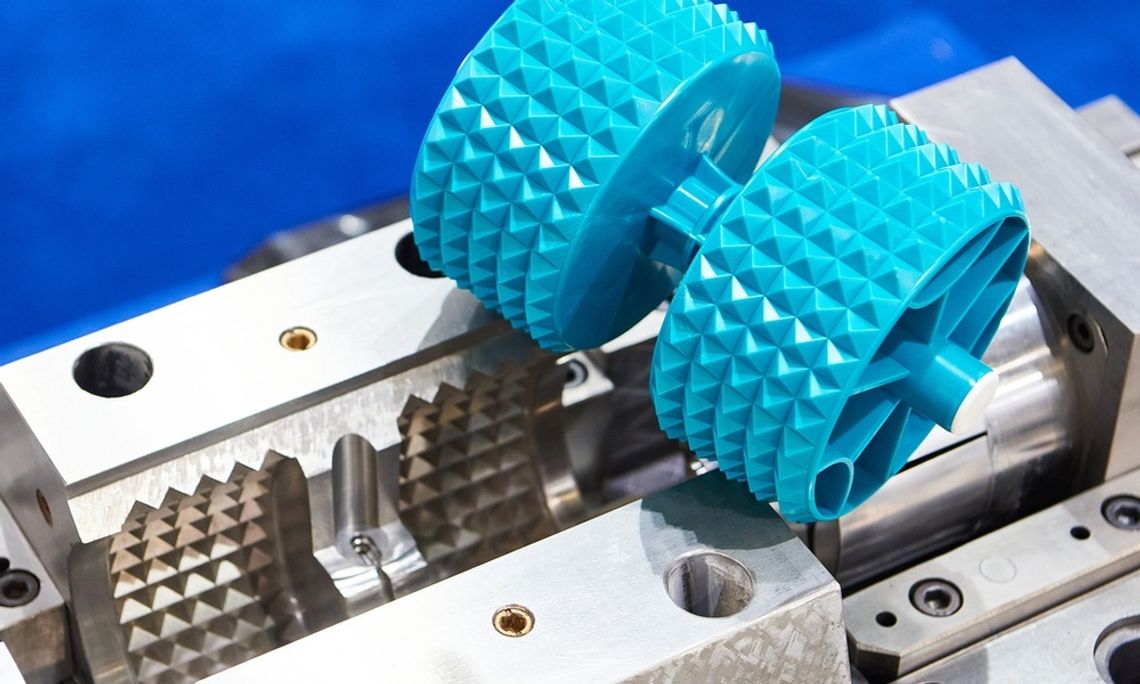

Streamlining mold design is one of the most effective ways to improve cooling efficiency. Well-designed molds with optimized cooling channel layouts enable consistent thermal management across every cycle. Using conformal cooling techniques, such as 3D-printed molds, can further enhance efficiency by allowing fluid to flow closer to the plastic surface. Testing and simulations can also help you identify heat distribution patterns—information that makes it easier to implement solutions going forward.

Choose the Right Coolant Flow Rates

Proper flow rate adjustments ensure that the coolant absorbs heat faster and maintains stable temperatures during production. Slow or inconsistent flow can lead to longer cooling times and uneven results. Determining the best operational mode for your air compressors is largely dependent on the chosen systems’ duty cycle ratings and demands of your applications. Many injection molding applications won’t demand uninterrupted flow, but if you are aiming for efficiency, you may want to consider if it’s possible to leverage constant flow in your setup. With a setup tailored to the unique needs and opportunities presented by your product, you can maximize performance while reducing unnecessary energy consumption.

Insulate Hot Surfaces

Reducing heat loss from hot surfaces minimizes energy waste and allows better heat transfer control. It’s possible to apply thermal insulation materials, such as ceramics or advanced polymers, to areas exposed to heat during operation. This approach not only supports cooling efficiency but also protects equipment from thermal wear, improving overall longevity. Insulation is particularly useful for molds and pipes that frequently encounter temperature differentials.

Maintain Your Cooling Systems Regularly

Over time, dirt, scaling, and wear can affect cooling system performance. Routine maintenance ensures these issues don’t escalate. Clean chiller systems, remove scaling in water piping, and monitor pumps and compressors to maintain consistent flow. Periodic inspections should also focus on finding cracks or leaks that could compromise coolant pathways. A regular maintenance schedule keeps systems running at peak performance, helping to make cooling more efficient for plastic parts and eliminating disruptions in manufacturing.

Explore Advanced Cooling Technologies

Emerging technologies offer promising solutions for improving cooling efficiency. For instance, waterless cooling systems or advanced chillers with improved energy conservation features can significantly enhance thermal regulation. Another option is leveraging automation to monitor and adjust temperature outputs dynamically during cycles. While these upgrades may require an upfront investment, the long-term savings can justify the costs, especially for facilities operating on high-volume production scales.

Small Changes Leading to Big Differences

Improving cooling efficiency doesn’t have to mean a complete system overhaul. Pairing optimized mold designs, proper flow rates, and preventive maintenance can deliver substantial results in reduced energy costs and faster cycle times. These efforts contribute to better product quality and a more sustainable manufacturing process.

With these steps, you can enhance performance today while preparing for tomorrow’s challenges.

Comment

Comments